Lockout/Tagout (LOTO) hazard assessments are crucial for workplace safety in industries with energy sources. OSHA's LOTO standards mandate employee training on lock and tag use, understanding different LOTO classes, and implementing communication protocols. Compliance training focuses on lockout/tagout programs, proper labeling, worker authorization before re-energizing, and using specific locking devices. Effective LOTO implementation through inspections, risk evaluations, and regular audits significantly reduces risks and maintains a safe work environment. Organizations should invest in tailored LOTO compliance training to ensure employees safely apply these safety measures according to OSHA guidelines.

“In today’s industrial landscape, ensuring safe energy control procedures is paramount. This article provides a comprehensive guide to LOTO (Lockout/Tagout) hazard assessments, a critical component of workplace safety. We’ll explore OSHA’s stringent lockout tagout standards, highlighting key regulations and requirements for compliance. Through in-depth training on energy control procedures, we delve into practical implementation strategies. Furthermore, we analyze the benefits and challenges associated with effective LOTO training, underscoring its transformative potential in enhancing overall safety.”

- Understanding LOTO Hazard Assessments: A Comprehensive Overview

- OSHA Lockout/Tagout Standards: Key Regulations and Requirements

- Energy Control Procedures Training: Essential Components for Compliance

- Practical Implementation of LOTO Hazard Assessments in the Workplace

- Benefits and Challenges: Enhancing Safety through Effective LOTO Training

Understanding LOTO Hazard Assessments: A Comprehensive Overview

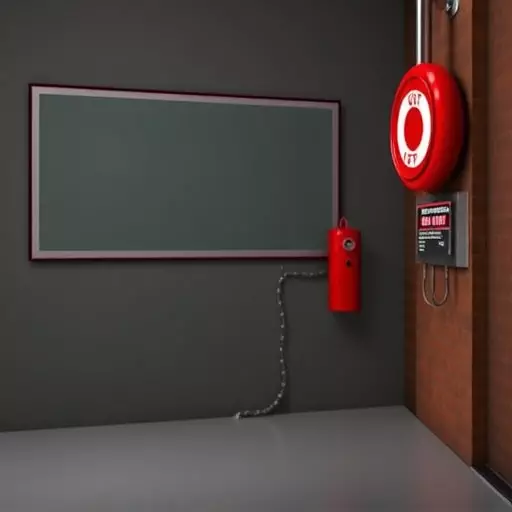

Lockout/Tagout (LOTO) hazard assessments are crucial components in ensuring workplace safety, especially in industries where energy sources are involved. These assessments focus on identifying and mitigating risks associated with powering down equipment for maintenance or repair, a process vital to preventing accidents and injuries. The primary goal is to create an energy control procedure that renders equipment and systems safe by applying specific LOTO methods.

OSHA (Occupational Safety and Health Administration) has established comprehensive lockout tagout standards to guide organizations in their efforts to maintain a secure working environment. This involves training employees on the proper use of locks and tags, understanding different LOTO classes, and implementing effective communication protocols. By adhering to these guidelines, companies can ensure that energy control procedures are rigorously followed, thereby fostering a culture of safety and compliance with lockout tagout regulations.

OSHA Lockout/Tagout Standards: Key Regulations and Requirements

OSHA Lockout/Tagout Standards serve as pivotal regulations designed to safeguard workers from hazardous energy sources during maintenance or repair activities. These standards are essential for establishments dealing with electrical, hydraulic, pneumatic, and other forms of energy in industrial settings. The primary objective is to ensure lockout tagout compliance training by implementing rigorous energy control procedures training.

Key requirements under these standards include the development and implementation of comprehensive lockout/tagout programs, proper labeling and tagging of de-energized equipment, worker authorization before re-energizing, and the use of specific locking devices. Compliance with OSHA lockout tagout standards is not just a legal necessity but also a critical step in preventing accidents, protecting personnel, and maintaining a safe working environment.

Energy Control Procedures Training: Essential Components for Compliance

Lockout/Tagout (LOTO) compliance training is an indispensable component in ensuring workplace safety, especially when dealing with energy sources. The OSHA (Occupational Safety and Health Administration) establishes standards for LOTO practices to prevent accidents related to uncontrolled releases of energy. Energy Control Procedures Training plays a pivotal role in equipping employees with the knowledge and skills necessary to comply with these standards. This training focuses on understanding the potential hazards associated with different energy sources, such as electrical, mechanical, and hydraulic systems.

The essence of this training lies in teaching employees effective lockout tagout techniques for various equipment and machinery. It involves learning how to properly isolate energy sources through the use of locks and tags, ensuring no residual energy remains active. By mastering these procedures, workers can confidently manage energy controls during maintenance or repair tasks, thereby minimizing risks and preventing serious injuries or fatalities.

Practical Implementation of LOTO Hazard Assessments in the Workplace

Lockout/tagout (LOTO) hazard assessments are a critical component of workplace safety, especially in industries where energy sources are frequently engaged or highly potent. These assessments ensure that all potential hazards associated with equipment and machinery are identified and mitigated to protect workers from injury or death. The practical implementation involves several key steps. Firstly, conduct thorough inspections to identify all energy sources connected to the equipment, such as electrical, hydraulic, pneumatic, or chemical. Once these are mapped out, a risk assessment should be performed to evaluate the likelihood and severity of potential harm.

Training plays a pivotal role in the successful execution of LOTO procedures. Providing employees with comprehensive lockout tagout compliance training ensures they understand energy control procedures and their significance. Understanding OSHA’s lockout tagout standards is essential here, as they dictate the protocols for de-energizing equipment safely. This includes the use of appropriate locking devices, clear communication among team members, and proper securing of locks to prevent accidental activation. Regular audits and updates to these assessments are necessary to maintain a safe work environment, especially with evolving machinery and energy systems.

Benefits and Challenges: Enhancing Safety through Effective LOTO Training

Lockout/tagout (LOTO) hazard assessments are crucial components in enhancing safety across industries where energy sources are involved. Effective LOTO compliance training, aligned with OSHA standards, plays a pivotal role in mitigating risks and preventing accidents. By implementing comprehensive lockout tagout procedures, organizations can ensure that equipment is properly secured before maintenance or repair, significantly reducing the potential for injuries.

Despite its importance, navigating LOTO practices comes with challenges. These include complex energy control procedures that require meticulous attention to detail, especially in environments with diverse energy sources and intricate systems. Additionally, ensuring worker comprehension and adherence to LOTO protocols can be demanding due to varying levels of training and experience. Therefore, organizations must invest in high-quality lockout tagout compliance training tailored to their specific operations, empowering employees to confidently and consistently apply these safety measures.